Selecting the right beer pump is crucial for any brewing operation, whether you're running a commercial brewery or setting up a home brewing system. The right beer pump ensures consistent flow rates, maintains product quality, and provides reliable performance throughout your brewing process. Understanding the different types of beer pump systems available and their specific applications will help you make an informed decision that matches your operational needs and budget requirements.

Understanding Beer Pump Types and Technologies

Magnetic Drive Pumps for Brewing Applications

Magnetic drive pumps represent one of the most popular choices for modern brewing operations due to their leak-free design and sanitary construction. These pumps eliminate the need for mechanical seals by using magnetic coupling to transfer power from the motor to the impeller. This design prevents contamination and ensures that your beer pump maintains the highest hygiene standards required in brewing applications.

The magnetic drive technology provides excellent chemical compatibility with brewing ingredients and cleaning solutions. Most magnetic drive beer pump models feature 304 or 316 stainless steel construction, which resists corrosion from acidic worts and alkaline cleaning chemicals. The absence of mechanical seals also reduces maintenance requirements and eliminates potential leak points that could compromise product quality.

Centrifugal Pump Systems for High Volume Operations

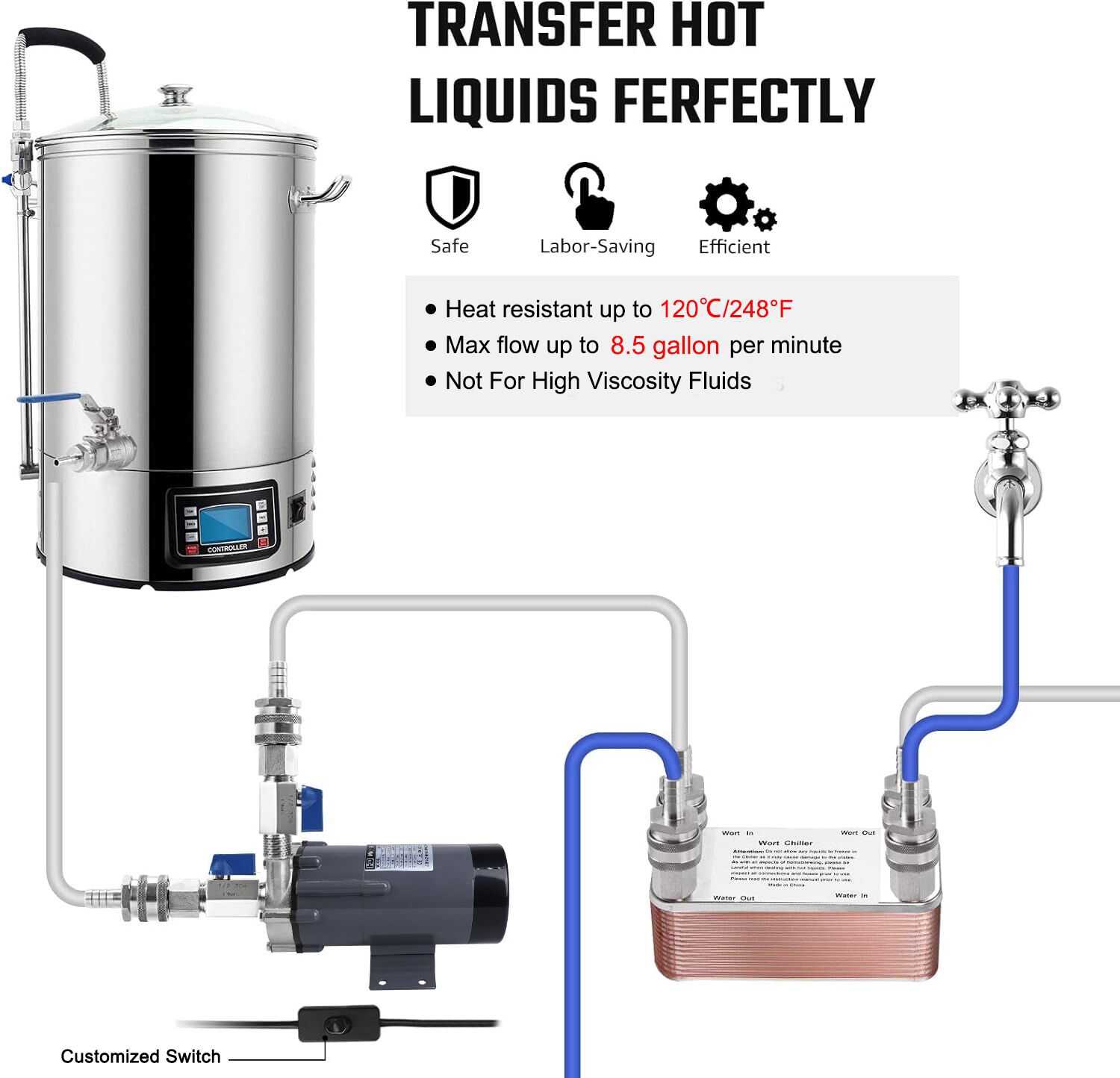

Centrifugal pumps offer exceptional flow rates and are ideal for large-scale brewing operations that require moving substantial volumes of liquid quickly. These pumps work by using centrifugal force to accelerate fluid through the pump housing, creating the pressure differential needed for fluid transfer. A well-designed centrifugal beer pump can handle flow rates from several gallons per minute to hundreds of gallons per minute, depending on the specific model and configuration.

When selecting a centrifugal beer pump, consider factors such as head pressure requirements, temperature limitations, and compatibility with your existing piping system. These pumps typically require priming before operation and work best with low-viscosity fluids like wort and finished beer. The efficiency of centrifugal pumps makes them cost-effective for continuous operation scenarios common in commercial brewing facilities.

Critical Selection Factors for Brewing Applications

Material Compatibility and Food Grade Requirements

Material selection plays a vital role in beer pump performance and product safety. Food-grade stainless steel, particularly 304 and 316 grades, provides excellent corrosion resistance and meets FDA requirements for food contact surfaces. The choice between these grades depends on your specific brewing environment and the types of cleaning chemicals you plan to use during sanitation procedures.

Beyond the pump housing materials, consider the compatibility of gaskets, seals, and other wetted components with your brewing process. EPDM and Viton seals offer excellent chemical resistance and temperature stability for most brewing applications. Some specialized brewing processes may require PTFE-lined components or other exotic materials to handle specific chemical conditions or extreme temperatures encountered during brewing operations.

Flow Rate and Pressure Requirements

Determining the appropriate flow rate and pressure specifications for your beer pump requires careful analysis of your brewing system layout and process requirements. Calculate the total system head, including static head from elevation changes, friction losses through piping and fittings, and any back-pressure from downstream equipment or processes.

Most brewing applications require moderate pressures and flow rates, but specific processes like filtration or carbonation may demand higher pressures. A typical home brewing beer pump might operate at 10-30 PSI with flow rates of 5-15 gallons per minute, while commercial operations may require pumps capable of 50-100 PSI and flow rates exceeding 100 gallons per minute. Always size your pump with some margin above your calculated requirements to account for system variations and future expansion needs.

Temperature Considerations and Thermal Management

High Temperature Applications in Brewing

Brewing processes often involve elevated temperatures that can challenge standard pump designs. Wort transfer during brewing typically occurs at temperatures between 150-212°F, requiring a beer pump capable of handling these thermal conditions without performance degradation. High-temperature applications demand careful attention to thermal expansion, seal materials, and motor cooling requirements.

When evaluating pumps for high-temperature service, verify that all wetted components can withstand your maximum operating temperature with adequate safety margin. Some pumps feature specialized high-temperature seals and thermal barriers to protect motor components from excessive heat. Proper installation practices, including thermal expansion compensation and adequate cooling, ensure reliable operation in demanding thermal environments.

Thermal Shock and Temperature Cycling

Brewing operations frequently subject equipment to rapid temperature changes during cleaning, sanitizing, and process transitions. These thermal shock conditions can stress pump components and lead to premature failure if not properly addressed. A robust beer pump design incorporates materials and construction techniques that accommodate thermal cycling without compromising performance or reliability.

Consider pumps with features like balanced thermal expansion, stress-relief designs, and materials specifically chosen for thermal cycling applications. Proper operating procedures, including controlled heating and cooling rates where possible, can extend pump life and reduce maintenance requirements in thermally demanding brewing environments.

Sanitary Design and Cleaning Compatibility

3-A Sanitary Standards and Industry Compliance

Sanitary design principles are paramount when selecting equipment for brewing applications. Look for pumps that meet or exceed 3-A sanitary standards, which specify design criteria for equipment used in food and beverage processing. These standards address surface finish requirements, drainage characteristics, and accessibility for cleaning and inspection.

A properly designed sanitary beer pump features smooth internal surfaces, minimal dead spaces, and complete drainability to prevent bacterial growth and product contamination. Tri-clamp connections provide reliable, sanitary joints that can be quickly disassembled for thorough cleaning and inspection. The pump design should facilitate both clean-in-place (CIP) and clean-out-of-place (COP) procedures commonly used in brewing facilities.

Chemical Compatibility with Cleaning Agents

Brewing equipment must withstand regular exposure to various cleaning and sanitizing chemicals, including caustic cleaners, acid rinses, and sanitizing solutions. Verify that your selected beer pump materials are compatible with all cleaning chemicals you plan to use, including concentration levels and temperature conditions during cleaning cycles.

Common brewing cleaning chemicals include sodium hydroxide (caustic), phosphoric acid, and various sanitizers like iodophors or peracetic acid solutions. Each of these chemicals can affect pump materials differently, particularly elastomeric seals and gaskets. Maintaining detailed chemical compatibility charts and following manufacturer recommendations helps ensure long-term equipment reliability and food safety compliance.

Installation and System Integration Considerations

Piping Design and System Layout

Proper system design significantly impacts beer pump performance and longevity. Plan your piping layout to minimize pressure losses, eliminate air pockets, and provide adequate support for the pump and connected piping. Consider factors such as pipe sizing, fitting selection, and the location of valves and instrumentation when designing your brewing system.

Self-priming capabilities become important when the pump must operate with suction lift or when the system frequently requires repriming. Some beer pump designs incorporate features that improve priming characteristics and reduce the risk of cavitation during startup. Proper venting and drainage provisions in the piping system support reliable operation and facilitate thorough cleaning procedures.

Electrical Requirements and Motor Selection

Electrical compatibility ensures seamless integration of your beer pump into existing facility infrastructure. Consider available voltage levels, phase requirements, and electrical load characteristics when selecting pump motors. Many brewing facilities operate on 220V single-phase or 480V three-phase power systems, requiring careful attention to motor specifications and electrical connections.

Variable frequency drives (VFDs) can provide significant benefits for brewing applications by allowing precise flow control and reduced energy consumption. When combined with appropriate instrumentation, VFD-controlled pumps enable automated process control and improved consistency in brewing operations. Evaluate the cost-benefit relationship of VFD systems based on your specific operational requirements and energy costs.

Performance Optimization and Efficiency

Energy Efficiency and Operating Cost Considerations

Energy efficiency directly impacts the long-term operating costs of your beer pump system. High-efficiency motor designs and optimized hydraulic performance can significantly reduce electricity consumption, particularly in applications with extended operating hours or high-duty cycles. Compare the energy consumption characteristics of different pump options using standardized efficiency metrics.

Consider the total cost of ownership when evaluating pump options, including initial purchase price, installation costs, energy consumption, and maintenance requirements. A more expensive pump with superior efficiency and reliability may provide better value over its operational lifetime compared to lower-cost alternatives with higher operating expenses or more frequent maintenance needs.

Maintenance Requirements and Service Life

Preventive maintenance programs extend beer pump service life and ensure consistent performance throughout the equipment's operational life. Evaluate maintenance requirements when selecting pumps, considering factors such as seal replacement intervals, bearing service life, and the complexity of routine maintenance procedures.

Pumps with simplified maintenance procedures and readily available spare parts reduce downtime and maintenance costs. Some designs feature cartridge-style seal assemblies that can be quickly replaced without extensive disassembly, while others may require more complex maintenance procedures. Factor these considerations into your equipment selection process, particularly for critical applications where downtime carries significant costs.

Sizing Guidelines for Different Brewing Applications

Home Brewing and Small-Scale Operations

Home brewing applications typically require compact, cost-effective pumps capable of handling batch sizes from 5 to 20 gallons. For these smaller systems, a beer pump with flow rates of 5-15 gallons per minute usually provides adequate performance for wort transfer, recirculation, and cleaning operations. Consider pumps with multiple connection options to accommodate various tubing sizes and fitting types commonly used in home brewing setups.

Temperature handling capability becomes particularly important for home brewing applications where space constraints may result in shorter cooling sections and higher operating temperatures. Look for pumps rated for continuous operation at temperatures up to 200°F to handle hot wort transfer operations safely. Portable mounting options and easy disassembly for cleaning make certain pump designs particularly well-suited for home brewing environments.

Commercial and Industrial Brewing Systems

Commercial brewing operations require robust pump systems capable of handling large volumes and continuous operation schedules. Flow rate requirements typically range from 50 to several hundred gallons per minute, depending on the brewery size and production capacity. Industrial beer pump installations often incorporate redundant systems to ensure continued operation during maintenance periods.

Automated control systems and process instrumentation become essential for commercial brewing operations to maintain consistency and efficiency. Consider pumps that integrate well with distributed control systems (DCS) or programmable logic controllers (PLC) commonly used in commercial facilities. Remote monitoring capabilities and diagnostic features help minimize unexpected downtime and optimize maintenance scheduling.

Quality Assurance and Testing Procedures

Performance Verification and Factory Testing

Reputable pump manufacturers provide comprehensive testing and quality assurance procedures to verify performance specifications and reliability. Factory testing typically includes performance curve verification, pressure testing, and material certification to ensure compliance with industry standards and customer requirements. Request test certificates and performance data when evaluating different beer pump options.

Hydrostatic pressure testing verifies the structural integrity of pump housings and connections under pressure conditions that exceed normal operating parameters. This testing helps identify potential failure modes and ensures safe operation throughout the pump's service life. Material certifications confirm that all wetted components meet food-grade requirements and chemical compatibility specifications.

Installation and Commissioning Best Practices

Proper installation and commissioning procedures ensure optimal beer pump performance and longevity. Follow manufacturer guidelines for foundation requirements, piping connections, and electrical installation to avoid problems that could affect pump operation or warranty coverage. Verify that all system components are properly supported and that thermal expansion provisions are adequate for your operating conditions.

Initial startup procedures should include verification of rotation direction, flow rate measurements, and pressure testing under actual operating conditions. Document baseline performance data to establish reference points for future maintenance and troubleshooting activities. Proper commissioning identifies potential issues before they impact production operations and ensures that warranty coverage remains valid throughout the equipment's service life.

FAQ

What size beer pump do I need for my brewing system?

The appropriate size depends on your batch volume, transfer distance, and required flow rate. For home brewing systems handling 5-10 gallon batches, a pump with 8-12 GPM capacity typically suffices. Commercial operations may require pumps handling 50-200+ GPM depending on production volume. Calculate your system head requirements including elevation changes and piping friction losses to determine the necessary pump pressure rating.

Can I use the same beer pump for both hot wort and finished beer?

Yes, provided the pump is rated for your maximum operating temperature. Most quality brewing pumps handle temperatures from near-freezing finished beer up to 200°F+ for hot wort transfer. Ensure all wetted components including seals and gaskets are rated for your temperature range. Consider thermal expansion effects on piping and pump mounting when transitioning between hot and cold applications.

How often should I replace seals and gaskets in my beer pump?

Replacement frequency depends on operating conditions, chemical exposure, and pump design. Magnetic drive pumps typically require less frequent seal replacement compared to mechanically sealed pumps. Monitor for leakage, performance degradation, or visible wear during routine inspections. Most brewery applications require seal replacement every 1-3 years depending on operating hours and maintenance practices.

What cleaning chemicals are safe to use with stainless steel beer pumps?

Most 304/316 stainless steel beer pumps safely handle common brewing chemicals including sodium hydroxide (caustic), phosphoric acid, and standard sanitizers. Avoid chloride-containing cleaners which can cause stress corrosion cracking in stainless steel. Always verify chemical compatibility with elastomeric components like seals and gaskets, as these may have more restrictive compatibility requirements than stainless steel wetted parts.

Table of Contents

- Understanding Beer Pump Types and Technologies

- Critical Selection Factors for Brewing Applications

- Temperature Considerations and Thermal Management

- Sanitary Design and Cleaning Compatibility

- Installation and System Integration Considerations

- Performance Optimization and Efficiency

- Sizing Guidelines for Different Brewing Applications

- Quality Assurance and Testing Procedures

- FAQ