Understanding how industrial pumping systems function is crucial for engineers, facility managers, and procurement specialists across various manufacturing sectors. A pneumatic diaphragm pump represents one of the most reliable and versatile solutions for handling challenging fluids in demanding applications. This comprehensive guide explores the fundamental principles, operational mechanisms, and practical applications of these essential industrial components, providing insights that help professionals make informed equipment decisions.

Industrial facilities worldwide depend on pneumatic diaphragm pump technology to transfer viscous materials, abrasive slurries, and chemically aggressive substances that would damage conventional centrifugal pumps. These positive displacement pumps utilize compressed air energy to create reciprocating diaphragm motion, generating consistent fluid movement without requiring electrical power at the pump location. Manufacturing plants appreciate the inherent safety benefits and operational flexibility these systems provide.

The growing adoption of pneumatic diaphragm pump solutions across industries reflects their proven ability to handle complex pumping challenges while maintaining operational reliability. From chemical processing and pharmaceutical manufacturing to food production and wastewater treatment, these pumps deliver consistent performance in applications where traditional pumping methods fall short. Their self-priming capabilities and ability to run dry without damage make them particularly valuable for intermittent duty cycles and remote installation locations.

Core Operating Principles

Air-Driven Mechanism

The fundamental operation of a pneumatic diaphragm pump relies on compressed air pressure alternately applied to opposing chambers separated by flexible diaphragms. When compressed air enters one chamber, it forces the diaphragm outward, creating suction that draws fluid through the inlet check valve while simultaneously pushing fluid out through the discharge check valve on the opposite side. This alternating pressure application creates continuous fluid flow without requiring mechanical shaft seals or electrical connections.

Air distribution within the pump occurs through a sophisticated valve system that automatically redirects compressed air flow between chambers at precise intervals. The pneumatic diaphragm pump achieves this switching action through a pilot valve mechanism that senses diaphragm position and triggers air flow reversal at optimal timing. This ensures smooth operation and maximizes pumping efficiency while minimizing wear on internal components.

Compressed air pressure directly correlates with pump discharge pressure, allowing operators to adjust output characteristics by modifying air supply pressure. Higher air pressure increases both flow rate and discharge pressure, while reduced air pressure provides gentler handling for shear-sensitive materials. This adjustability makes the pneumatic diaphragm pump ideal for applications requiring variable flow rates or pressure conditions throughout different process stages.

Diaphragm Function

Diaphragms serve as the primary moving components within pneumatic diaphragm pump assemblies, converting pneumatic energy into hydraulic pressure through flexible membrane displacement. These engineered components must withstand repeated flexing cycles while maintaining chemical compatibility with processed fluids and air-side environments. Material selection for diaphragms considers factors including temperature resistance, chemical compatibility, abrasion resistance, and fatigue life.

The diaphragm assembly typically consists of multiple layers designed to optimize performance and reliability. Inner layers provide chemical resistance and fluid compatibility, while outer layers offer mechanical strength and air-side durability. A pneumatic diaphragm pump utilizes specialized diaphragm geometries that maximize displacement volume while minimizing stress concentrations that could lead to premature failure.

Diaphragm deflection patterns influence pump performance characteristics including flow rate, pressure capability, and component longevity. Proper diaphragm design ensures complete fluid evacuation from pump chambers while preventing excessive stretching that reduces service life. Advanced diaphragm materials and construction techniques enable modern pneumatic diaphragm pump systems to achieve millions of operating cycles in demanding industrial applications.

System Components and Design

Air Distribution System

The air distribution system controls pneumatic energy flow within the pump assembly, ensuring proper timing and pressure application for optimal performance. Central to this system is the air valve mechanism that alternately directs compressed air to opposing diaphragm chambers while simultaneously venting the opposite chamber to atmosphere. This valve system must operate reliably under varying pressure conditions and process environments.

Pilot valves within the air distribution system sense diaphragm position and trigger switching actions at precise moments in the pumping cycle. These components utilize ingenious mechanical or pneumatic feedback mechanisms that detect when diaphragms reach maximum displacement, initiating air flow reversal for continuous operation. The pneumatic diaphragm pump achieves consistent performance through careful calibration of these switching mechanisms.

Air supply requirements for pneumatic diaphragm pump operation include adequate pressure, flow capacity, and air quality considerations. Compressed air must be free from moisture, oil, and particulate contamination that could interfere with valve operation or contaminate processed fluids. Proper air filtration, regulation, and lubrication systems ensure reliable pump operation and extended component life.

Fluid Handling Components

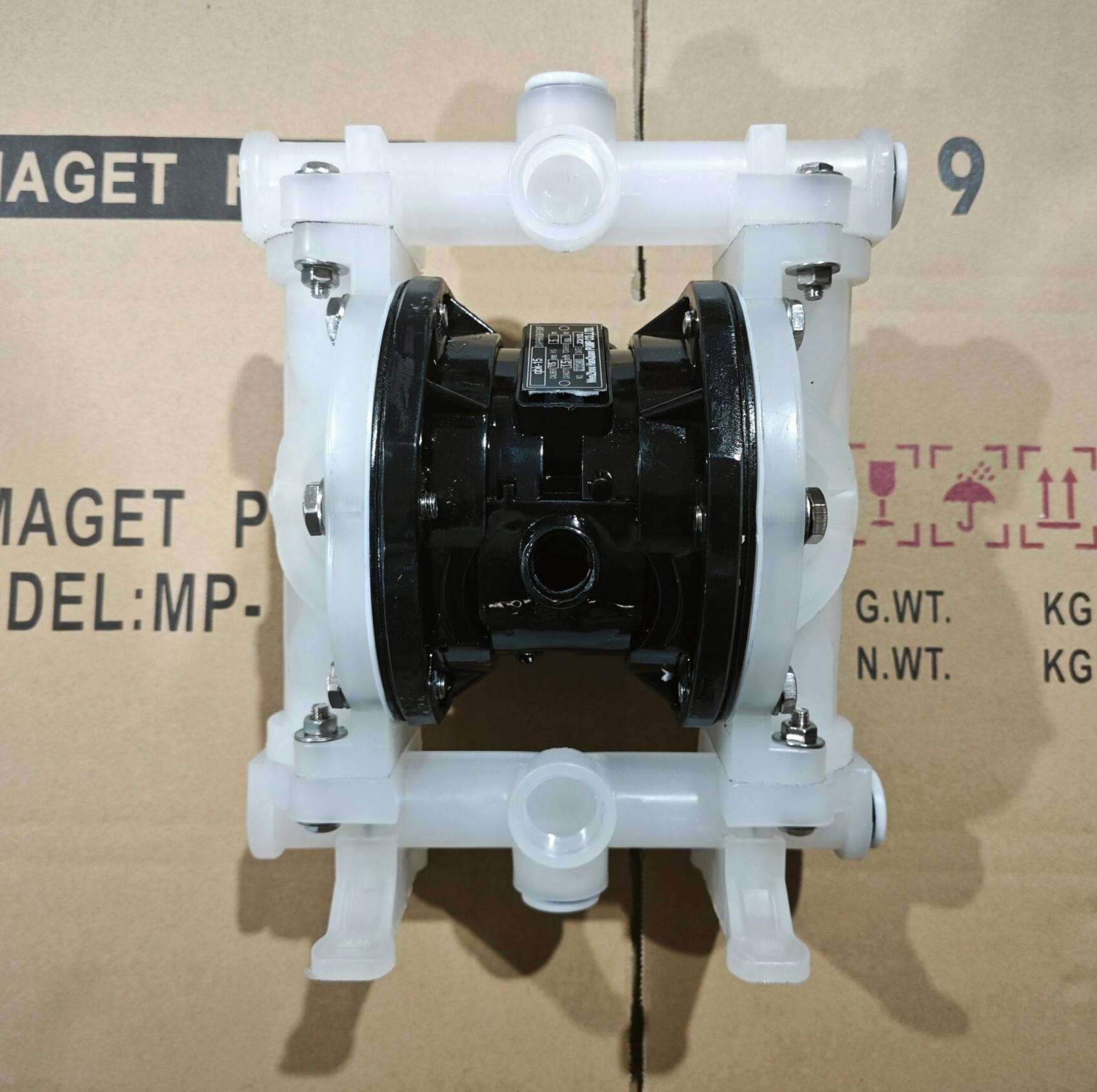

Fluid-wetted components within pneumatic diaphragm pump assemblies must demonstrate exceptional chemical compatibility and mechanical durability. Pump bodies, typically manufactured from materials such as polypropylene, aluminum, or stainless steel, provide structural integrity while resisting chemical attack from processed fluids. Material selection depends on specific application requirements including temperature, pressure, and chemical compatibility considerations.

Check valves control fluid flow direction within the pump, opening to allow flow during suction and discharge phases while preventing backflow during pressure reversal. These critical components must provide reliable sealing under varying pressure differentials while minimizing flow restriction. Ball check valves, flap valves, and diaphragm check valves each offer specific advantages depending on fluid characteristics and application requirements.

Inlet and outlet manifolds connect the pneumatic diaphragm pump to process piping systems while accommodating thermal expansion and vibration isolation requirements. These components often incorporate features such as drain ports, pressure relief capabilities, and mounting provisions for instrumentation. Proper manifold design ensures efficient fluid transfer while facilitating maintenance access and system integration.

Operational Advantages

Safety and Reliability Benefits

Safety considerations make pneumatic diaphragm pump technology particularly attractive for hazardous material handling applications. The absence of electrical components at the pump location eliminates ignition sources in flammable atmospheres, while the air-driven operation prevents sparking that could trigger explosions. This intrinsic safety makes these pumps ideal for transferring volatile solvents, combustible chemicals, and other potentially dangerous substances.

Leak containment represents another significant safety advantage of pneumatic diaphragm pump designs. The diaphragm barrier prevents process fluid contact with air-side components, while pump design typically incorporates provisions for detecting and containing diaphragm failures. Many installations include leak detection systems that automatically shut down operations if diaphragm integrity is compromised, preventing environmental releases or personnel exposure.

Operational reliability stems from the simple mechanical design and absence of wearing components such as mechanical seals or bearings. A pneumatic diaphragm pump can operate continuously for extended periods with minimal maintenance requirements, reducing downtime and operational costs. The ability to run dry without damage provides additional operational flexibility, particularly in applications with intermittent fluid supply or automatic control systems.

Performance Characteristics

Self-priming capability allows pneumatic diaphragm pump systems to begin operation immediately without manual priming procedures. This feature proves particularly valuable in applications where suction lift is required or where pumps must restart automatically after power outages or maintenance shutdowns. The positive displacement pumping action maintains consistent flow rates regardless of system backpressure variations.

Variable flow control through air pressure adjustment provides operational flexibility without requiring expensive variable frequency drives or complex control systems. Operators can modify pump output to match process requirements simply by adjusting compressed air supply pressure. This capability enables precise flow control for batching operations, material metering, and process optimization applications.

Gentle fluid handling characteristics make pneumatic diaphragm pump technology suitable for shear-sensitive materials such as food products, pharmaceuticals, and specialty chemicals. The pulsating flow pattern minimizes fluid shear compared to centrifugal pumps, preserving product quality and reducing degradation of sensitive compounds. This gentle handling extends product shelf life and maintains critical material properties throughout processing operations.

Industrial Applications

Chemical Processing

Chemical manufacturing facilities rely on pneumatic diaphragm pump systems for transferring corrosive acids, caustic solutions, and reactive chemicals that would quickly destroy conventional pumping equipment. The chemical resistance of properly selected diaphragm materials and wetted components ensures reliable operation in these demanding environments. Process engineers appreciate the ability to handle varying fluid viscosities and suspended solids without performance degradation.

Batch processing operations benefit from the precise flow control and self-priming capabilities of pneumatic diaphragm pump technology. These pumps can accurately meter chemical additions, transfer precise volumes between process vessels, and handle the start-stop cycling common in batch manufacturing. The pneumatic diaphragm pump excels in applications requiring frequent product changeovers or cleaning cycles.

Waste stream management in chemical facilities often involves handling contaminated solutions, spent catalysts, and byproduct materials with challenging characteristics. Pneumatic diaphragm pump systems can reliably transfer these difficult materials without clogging or excessive wear, reducing maintenance costs and environmental compliance risks. Their ability to handle varying solids concentrations makes them ideal for waste treatment applications.

Food and Beverage Production

Food processing applications demand pumping equipment that maintains product quality while meeting stringent sanitary requirements. Pneumatic diaphragm pump designs can incorporate food-grade materials and sanitary connections that comply with FDA regulations and industry standards. The gentle pumping action preserves product texture and prevents emulsion breakdown in sensitive food products.

Cleaning and sanitization procedures in food facilities require pumping systems capable of handling hot cleaning solutions, sanitizers, and steam condensate. A pneumatic diaphragm pump can typically withstand these cleaning chemicals without degradation, while the simple design facilitates thorough cleaning between product runs. This capability reduces contamination risks and supports compliance with food safety regulations.

Beverage production often involves transferring flavoring syrups, concentrated juices, and other viscous materials that challenge conventional pumps. Pneumatic diaphragm pump technology handles these materials effectively while preventing product degradation that could affect taste or appearance. The ability to handle varying product viscosities without adjustment makes these pumps valuable in facilities producing multiple beverage types.

Maintenance and Optimization

Routine Maintenance Requirements

Preventive maintenance for pneumatic diaphragm pump systems focuses primarily on diaphragm inspection and replacement, as these components experience the most wear during operation. Maintenance schedules should consider factors such as operating hours, fluid characteristics, and environmental conditions that affect diaphragm life. Regular inspection allows maintenance teams to identify wear patterns and optimize replacement intervals.

Air system maintenance ensures reliable pump operation by maintaining proper compressed air quality and pressure regulation. This includes regular replacement of air filters, drainage of moisture from air lines, and calibration of pressure regulators. Contaminated compressed air can cause valve malfunctions and reduce component life, making air system maintenance critical for pneumatic diaphragm pump reliability.

Check valve inspection and cleaning prevent performance degradation caused by debris accumulation or wear. These components should be examined regularly for proper sealing and flow characteristics, with replacement recommended when leakage or flow restriction becomes apparent. Proper check valve maintenance ensures optimal pump efficiency and prevents fluid backflow that could contaminate upstream systems.

Performance Optimization

System tuning involves adjusting air pressure, flow rates, and timing parameters to optimize pneumatic diaphragm pump performance for specific applications. Proper tuning can improve efficiency, reduce energy consumption, and extend component life while maintaining required flow and pressure specifications. Performance monitoring helps identify optimization opportunities and potential maintenance needs.

Fluid compatibility assessments ensure that pump materials remain suitable for evolving process requirements or product formulations. Regular evaluation of diaphragm materials, valve components, and pump body materials helps prevent unexpected failures and maintains operational reliability. Material upgrades may be necessary as process conditions change or new fluid types are introduced.

Energy efficiency improvements can be achieved through proper system design and operation optimization. This includes minimizing pressure drops in suction and discharge piping, optimizing air pressure settings, and implementing control systems that adjust pump operation to match process demands. Efficient pneumatic diaphragm pump operation reduces compressed air consumption and operational costs.

FAQ

What makes pneumatic diaphragm pumps suitable for hazardous environments

Pneumatic diaphragm pumps excel in hazardous environments because they contain no electrical components at the pump location, eliminating ignition sources that could trigger fires or explosions. The air-driven operation prevents sparking, while the robust diaphragm barrier prevents process fluid leaks from contaminating the surrounding area. These safety features make them ideal for handling flammable solvents, toxic chemicals, and other dangerous materials in compliance with safety regulations.

How do you select the right diaphragm material for specific applications

Diaphragm material selection requires careful consideration of chemical compatibility, temperature resistance, and mechanical properties. Common materials include PTFE for aggressive chemicals, Viton for high-temperature applications, and Santoprene for food-grade requirements. Consulting chemical compatibility charts and considering factors such as operating temperature, pressure, and expected service life helps ensure optimal material selection for reliable pneumatic diaphragm pump operation.

Can pneumatic diaphragm pumps handle solids and abrasive materials

Yes, pneumatic diaphragm pumps can effectively handle suspended solids, slurries, and mildly abrasive materials due to their positive displacement design and large internal flow passages. The gentle pumping action minimizes particle degradation while the robust construction withstands moderate abrasion. However, particle size should be limited to prevent check valve interference, and pump materials should be selected to resist abrasive wear for optimal service life.

What maintenance indicators suggest diaphragm replacement is needed

Key indicators for diaphragm replacement include reduced flow rate, increased air consumption, visible fluid leakage from pump vents, and irregular pumping rhythm. Preventive maintenance programs should track operating hours and cycles to predict replacement timing, while performance monitoring helps identify gradual degradation before complete failure occurs. Regular inspection of diaphragm condition during routine maintenance allows for planned replacement and prevents unexpected downtime in critical pneumatic diaphragm pump applications.